Specialized in fabrication of these machines for 25 years and this enables us to be a leader in the field of Gold Processing Plant & Equipment

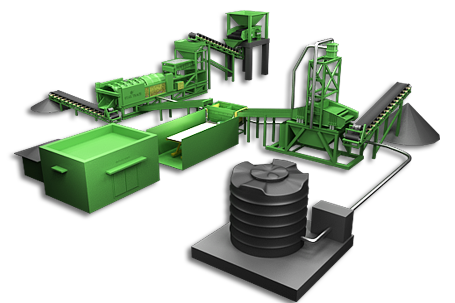

Gold Processing Plants

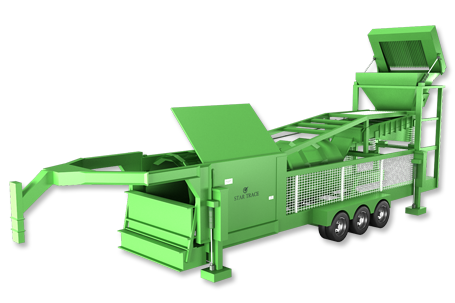

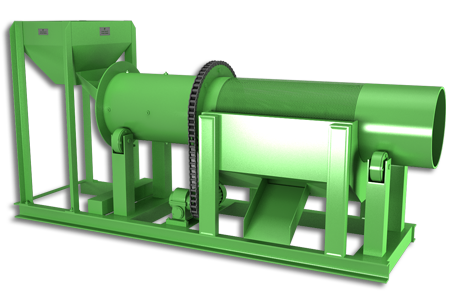

Star Trace offers turnkey solutions for gold processing plants. Specialized in the fabrication of these machines for 25 years and this enables us to be in a leading position in the field of gold processing plant & equipment. We specialize in gold processing plants, gold trommel plants and portable gold trommel plants.

Gold Processing Machineries

Star Trace is one of the leading project suppliers for gold plants and we work closely with our customers to fulfil their specific needs. Our array of gold processing machineries includes: Slurry Pumps, Gold Concentrator, Shaking Table for Gold, Mineral Jig for Gold, Dewatering Screen for Gold, etc.

Welcome to Star Trace Solutions Private Limited

About us

We,Star Trace Solutions Pvt. Ltd., established our operations in the year 1991, as one of the glorious ISO 9001:2008 certified manufacturers, exporters and suppliers of an unlimited collection of Industrial Separators & Magnetic Equipment.

Our product collection comprises of Magnetic Separators, Overband Magnets and Magnetic Roll Separators that can be availed in multiple specifications to cater to the varied customer requirements.

In addition to the exceptional range, we are famous for our installation, fabrication and erection services carried out by our experienced service engineers.

Our Company Quality Assurance has been supported & approved by "THE INTERNATIONAL ORGANIZATION FOR STANDARTIZATION"(ISO 9001:2008), NSIC & also by the NABCB-QM0II and D&B where you can get the company certified details by On-line.

Geared with the latest technology and manufacturing equipment, we have set down for ourselves a set of objectives that have always guided us to give a better performance.

- To provide our customers with a consistent level of satisfaction at all times.

- To always nurture the culture of teamwork for achieving our target production capacity within the stipulated time frame.

- To achieve a wider client base and also to exceed their expectations by means of modern and cost effective technology.

- Metal forming

- Cutting

- Welding

- Casting

- Sintering

- Pressing

- Extrusion

- Calendering

Since we are engaged in manufacturing as well as in offering turnkey projects to our customers, we pay utmost attention to customer's specific demands and requirements. We take pride in our ability to tend to all the demands made by the customers concerning designing, fabrication, erection, installation or any other work.

Our personnel ensure that the client's requirements are met with within the stipulated time frame and at industry leading prices. These endeavours are taken care of by obtaining the drafts of their designs or site maps for installation, erection etc.

Our Clients